In the realm of modern design and manufacturing, custom aluminum products have taken center stage. From sleek electronics to sturdy building materials, the use of custom aluminum has permeated various industries, showcasing its versatility and numerous advantages. In this article, we’ll delve into the world of custom aluminum, exploring its applications, benefits, and the reasons behind its widespread popularity.

Table of Contents

- Introduction

- The Manufacturing Process of Custom Aluminum

- Applications in Electronics and Technology

- Custom Aluminum in the Automotive Industry

- Sustainable Building Solutions with Custom Aluminum

- Advantages of Choosing Custom Aluminum Products

- Custom Aluminum vs. Other Materials: A Comparative Analysis

- Innovations in Custom Aluminum Design

- How to Select the Right Custom Aluminum Manufacturer

- The Future of Custom Aluminum Creations

- Conclusion

- FAQs

- What makes aluminum a suitable choice for custom products?

- Are there any limitations to using custom aluminum in construction?

- How does custom aluminum contribute to sustainability?

- Can I recycle custom aluminum products?

- What role does design play in the popularity of custom aluminum creations?

Introduction

Aluminum, a lightweight and corrosion-resistant metal, has become a go-to material for customization across various industries. Its unique properties make it an ideal choice for crafting bespoke products that align with the evolving needs of today’s consumers.

The Manufacturing Process of Custom Aluminum

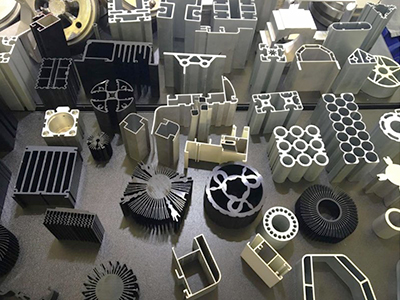

Custom aluminum products are typically fabricated through a meticulous process that involves precision cutting, shaping, and finishing. Manufacturers employ advanced techniques such as CNC machining to ensure every detail of the design is accurately translated into the final product.

Applications in Electronics and Technology

The electronics industry has embraced custom aluminum for its sleek appearance, durability, and excellent heat-dissipation properties. Laptops, smartphones, and other gadgets are now encased in intricately designed aluminum shells that offer both protection and aesthetics.

Custom Aluminum in the Automotive Industry

In the automotive world, custom aluminum components have revolutionized vehicle performance and fuel efficiency. From lightweight frames to engine parts, aluminum’s high strength-to-weight ratio contributes to enhanced overall performance.

Sustainable Building Solutions with Custom Aluminum

Custom aluminum plays a pivotal role in sustainable architecture. Its recyclability, coupled with its ability to withstand harsh environmental conditions, makes it an excellent choice for eco-friendly building designs that stand the test of time.

Advantages of Choosing Custom Aluminum Products

The advantages of custom aluminum products are manifold. They include exceptional durability, resistance to corrosion, low maintenance requirements, and the ability to be tailored to specific design preferences.

Custom Aluminum vs. Other Materials: A Comparative Analysis

In comparison to other materials like steel or plastic, custom aluminum holds its own in terms of strength and versatility. Its lightweight nature and resistance to rust set it apart from traditional options.

Innovations in Custom Aluminum Design

As technology advances, so does the realm of custom aluminum design. Intricate patterns, laser engravings, and textured finishes are now possible, allowing for highly personalized and visually striking creations.

How to Select the Right Custom Aluminum Manufacturer

Choosing the right manufacturer is crucial for the success of any custom aluminum project. Factors to consider include experience, capabilities, turnaround time, and adherence to design specifications.

The Future of Custom Aluminum Creations

The future of custom aluminum looks promising, with ongoing research into alloy compositions, surface treatments, and sustainable practices. This paves the way for even more innovative and eco-friendly applications.

Conclusion

In a world where personalization and quality reign supreme, custom aluminum has emerged as a frontrunner. Its adaptability across various sectors, coupled with its remarkable attributes, positions it as a material that not only meets but exceeds the demands of modern consumers.